Knox Masonry

Historic Masonry Restoration Specialists

Historic Masonry Restoration with Knox Masonry

Historic Masonry

Successful restoration projects depend on the masons themselves. Experienced masons understand the special requirements for work on historic buildings and the added time and expense they require.

The entire masonry crew must be willing and able to perform the work in conformance with the specifications set forth by the National Park Service and others, even when the specifications may not be in conformance with standard practice.

A good restoration job is meant to last at least 30 years or more. Shortcuts and poor craftsmanship result not only in diminishing the historic character of a building, but also in a job that looks bad, and will require future work sooner than if the work had been done correctly. Good restoration practices guarantee a long life the historic structure. Careful maintenance will help preserve the building for decades to come.

FAQS

As a historic masonry expert, what is the first thing you do when you get a job like this?

Most projects begin with a series of meetings usually with a Board of Trustees, Architects and Engineers. Occasionally a representative from the States Historic preservation commission will attend. These people are a mix of volunteers and professionals who are dedicated to monitoring the entire project from start to finish.

We discuss all of the specific needs of the project and address and questions that may come up. Meetings are held every two weeks or so. Various issues are discussed during these meetings, from the timelines, progress, and changes that are needed to the project plan. Communication is Paramount in a historic renovation project so everything syncs together to make for a successful outcome.

How do you know if a building is in need of repair?

It's hard to pinpoint exactly how long this building was in need of repairs. A good indicator is when you notice the mortar "breaking down" or when it has lost its "bond" from the surrounding masonry material. Water infiltration is also another good indicator that your building facade is failing.

Where do you get your supplies to work on historic buildings? And how did you formulate the exact formula for this.?

When possible all the materials are salvaged during the demolition phase. The one thing that makes this type of work unique is that you can't run down to your local building supply store and grab a stone from 1887. Over the years we have developed a network of suppliers all over the United States and Canada.

When it comes to mortar matching the process starts with a series of samples taken from the project. This part can be tricky because usually many repairs have been done on these building over the years. You have to be aware you're not taking a sample from the 1920's rather than the original from the 1800's. Getting a "feel" and yes even a "smell" of the original comes with practice. I've have been known to "taste" an old mortar mix for confirmation that's it's original.

Once the sample is collected it is sent out to one of several laboratories we have partnered with all over the United States. There a complex analysis is performed to measure all of the elements that the mortar contains. They test for lime content, the presence of Portland cement and also the type of sand used. Sand type can make a huge difference in the final mortar mix that is trying to be replicated. Sand can be "sharp", "round" it can also be black, white, yellow or a mix of all of the characteristics. The test will determine the exact ratio of all of these elements.

Once a report is generated, we determine if we will replicate the historic mixture ourselves or have a professional company produce it for us. The final phase takes patience as we "dial in" a mix. Most times the final color has to be tweaked to match the original mortar. This process can take several attempts before it is approved by the project overseers.

View one of our historic projects below

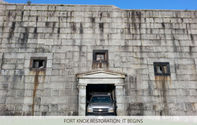

Masonry Repair Project at Fort Knox

WABI Video

Fort Restoration complete, click here

Friends of Fort Knox Newsletter

Fort Knox undergoes masonry work

Bangor Daily News